Fuel efficiency is a big-league element in the field of aircraft operations. Evolution of an aircraft goes commensurately with evolution of fuel efficiency, which largely depends on the weight of the aircraft. A few years ago, the researchers of HRL Laboratories in a joint venture with Boeing created the world’s lightest metal called Microlattice having a density of 0.9 mg/cm3. [highlight ]Beating the previous record of 1 mg/cm3 of silica aerogels and being among the lowest dense solids, this metal is 100 times lighter than styrofoam but is as strong as most of the metals.[/highlight]

Boeing claims that the metal is ready but hasn’t cleared anything about its use in their aircraft any time soon.

Boeing has now unveiled the first ever video of Microlattice, demonstrating the properties and potential applications of the lightest metal that humans have ever created.

Microlattice is a lattice of interconnected hollow tubes of thickness 100 nano meters which is 1,000 times thinner than the human hair. Net composition of Microlattice is 99.99% air and remaining of Nickel and Phosphorous alloy.[highlight ]Net composition of Microlattice is 99.99% air and remaining of Nickel and Phosphorous alloy.[/highlight]

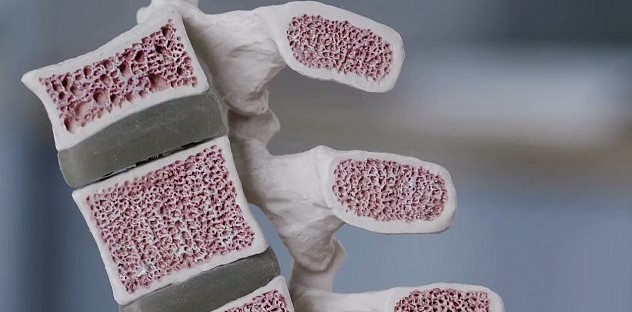

Structure of Microlattice is highly influenced by human bones, which possess a rigid structure from outside but consist of hollow tubes from the inside which bring lightness on par with the strength. This kind of structure also provides the ability to absorb a whole lot of energy, as an egg wrapped in Microlattice would survive a drop from a 25 story building. They completely recover their shape after significant compression.

Sophia Yang, a research scientist at HRL Laboratories who worked on the project said that [highlight ]Microlattice could find its way into the aircraft industry through flooring, seat frames and walls.[/highlight] After seeing the potential of the material, Boeing can build light-weight aircrafts but just as tough as the ones today but a whole lot more fuel efficient.

Other potential applications of Microlattice include thermal and vibration insulators, battery electrodes and catalyst supports.